Slip-on Flanges | Slip-on Flanges Exporter | Slip-on Flanges Manufacturer in India | SS Slip-on Flanges Price | Best Quality Slip-on Flanges | Carbon Steel Slip on Flanges Supplier | Stainless Steel Slip-on Flanges Stockists

Tejdeep Steels is a renowned Slip-on Flanges manufacturer, supplier, stockist, and exporter based in India. Our slip-on flanges are specifically designed to cater to a wide range of industrial applications. We offer slip-on flanges in multiple standards, sizes, grades, and materials such as Stainless Steel slip-on flanges, Carbon Steel slip-on flanges, Alloy Steel slip-on flanges, and others. Our unwavering commitment to delivering slip-on flanges that surpasses the industry standards is our point of pride.

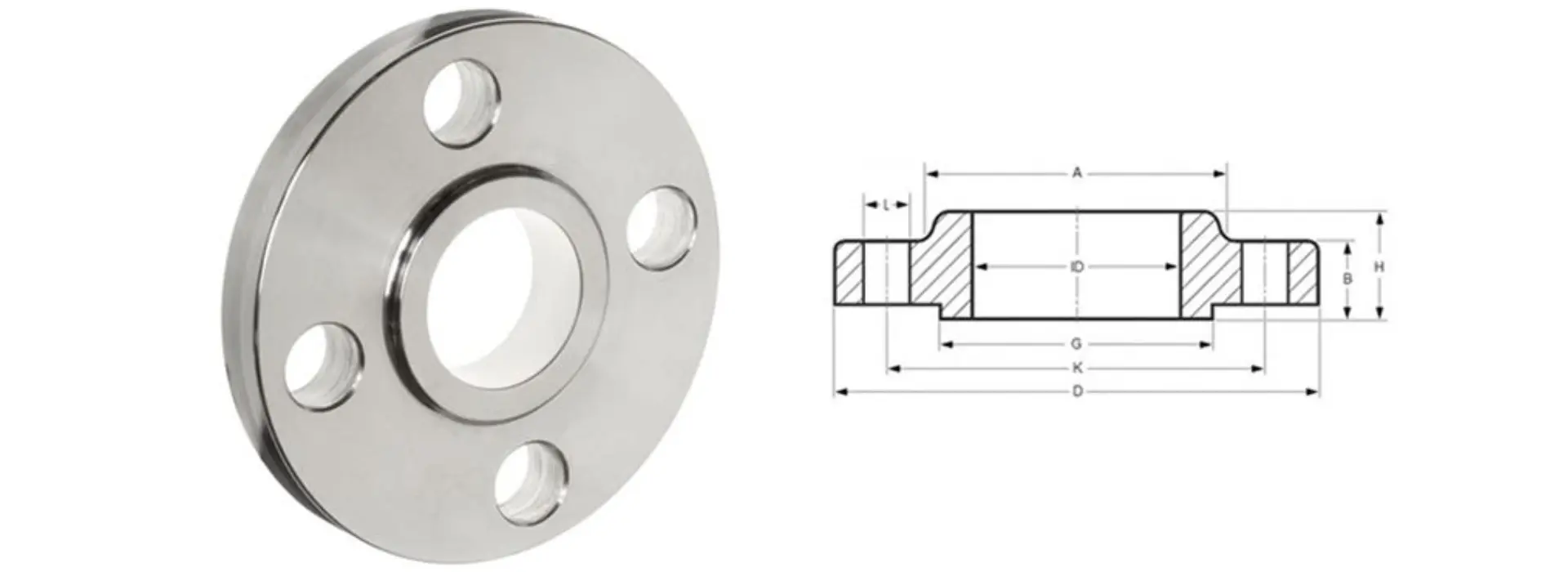

Our Slip-on Flange Dimensions are carefully designed to ensure a precise fit for your specific requirements. Whether you need Raised Face Slip-on Flanges or Flat-face Slip-on Flanges, we have the perfect solution. Our slip-on flanges are compliant with ANSI slip-on flanges, ASME slip-on-flanges, and DIN slip-on-flanges standards, guaranteeing their quality and reliability.

Slip-on Flanges Manufacturers in India

Slip-on flanges are a type of flange used to create a secure connection between two pipes or fittings. As the name suggests, slip-on flanges are designed to slip over the end of the pipe and are then welded in place. They have a flat sealing face and a raised collar (hub) around the inner diameter to provide additional strength and support. Slip-on flanges are widely used in various industries for their simplicity, ease of installation, and cost-effectiveness. As slip-on flanges, manufacturers in India in various materials, sizes, specifications, etc.

Properties of Slip-On Flanges

Slip-on flanges possess several properties that make them suitable for specific applications in various industries. Here are the key properties of slip-on flanges:

- Easy installation with minimal alignment required.

- Cost-effective option for flange connections.

- Versatile and compatible with various pipe materials.

- Available in different pressure ratings.

- Resilient to thermal expansion and contraction.

- Suitable for low-pressure systems.

- Capable of being welded for added strength.

- Space-saving design for efficient installation.

Slip-on Flanges Specification, Grades, Size, & Materials

| ASME B16.9 Slip on Flange Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| ASME B16.5 SORF Plate Flanges Size | 1/2″ (15 NB) to 48″ (1200NB) |

| ASME B16.5 SORF Pipe Flanges Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Flange Face Type | ASME B16.9 Flate Face (FF), ASME B16.9 Raised Face (RF), ASME B16.9 Ring Type Joint (RTJ) |

| Value-Added Services | CNC Machining, Customised Flanges |

| Slip-on Raised Face Flanges For DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| Stainless Steel slip on flange flat face For BS | BS4504 , BS4504, BS1560, BS10 |

| Slip-On Flange Manufacturers & Coating/Surface Treatment | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Grades | ||||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | |||

| Super Duplex Steel | S32750 | |||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | |||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | |||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | |||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | |||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | |||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | |||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | |||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | |||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | |||

| Niobium | ASTM B394, R04200 R04210 | |||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | |||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | |||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | |||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | |||

| Tantalum | Tantalum – Grade 1. | |||

| Monel | Monel 400, Monel k500 | |||

| MU-METAL | MU-METAL | |||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | |||

| Beryllium Copper | Alloy 25 UNSC17200 | |||

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | |||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | |||

Types Of Slip-on Flanges

Stainless Steel Slip-on Flanges Manufacturer

Carbon Steel Slip-on Flanges Supplier

Duplex Steel Slip-on Flanges Flange Stockists

Slip-on Flanges Application & Uses

- Slip-on Flanges used in Transporting materials

- Stainless Steel Slip-on Flanges used in the Automotive industry

- Slip-on Flanges used in Homes and buildings

- SS Slip-on Flanges are used in Sewerage systems and industrial water lines.

- Carbon Steel Slip-on Flanges are used in heating and air-conditioning equipment.

- Slip-on Flanges used in Plumbing

- Alloy Slip-on Flanges used in Food Processing Industry

- Slip-on Flanges used in the Paper & Pulp Industry

- Slip-on Flanges used in Food Industry

ASTM / ASME / AISI Slip-on Flanges Dimension & Sizes

|

ANSI/ASME/ASA B16.5 150lb/sq.in. Flanges SO-RF

|

||||||||||

|

ø

|

D

|

b

|

g

|

m

|

J

|

h

|

k

|

Holes

|

l

|

Kg.

|

|

1/2″

|

88,9

|

11,1

|

34,9

|

30,2

|

22,3

|

15,9

|

60,3

|

4

|

15,9

|

0,400

|

|

3/4″

|

98,4

|

12,7

|

42,9

|

38,1

|

27,7

|

15,9

|

69,8

|

4

|

15,9

|

0,700

|

|

1″

|

107,9

|

14,3

|

50,8

|

49,2

|

34,5

|

17,5

|

79,4

|

4

|

15,9

|

0,800

|

|

1 1/4″

|

117,5

|

15,9

|

63,5

|

58,8

|

43,2

|

20,6

|

88,9

|

4

|

15,9

|

1,100

|

|

1 1/2″

|

127,0

|

17,5

|

73,0

|

65,1

|

49,5

|

22,2

|

98,4

|

4

|

15,9

|

1,400

|

|

2″

|

152,4

|

19,0

|

92,1

|

77,8

|

62,0

|

25,4

|

120,6

|

4

|

19,0

|

2,200

|

|

2 1/2″

|

177,8

|

22,2

|

104,8

|

90,5

|

74,7

|

28,6

|

139,7

|

4

|

19,0

|

3,600

|

|

3″

|

190,5

|

23,8

|

127,0

|

107,9

|

90,7

|

30,2

|

152,4

|

4

|

19,0

|

4,100

|

|

3 1/2″

|

215,9

|

23,8

|

139,7

|

122,2

|

103,4

|

31,7

|

177,8

|

8

|

19,0

|

5,200

|

|

4″

|

228,6

|

23,8

|

157,2

|

134,9

|

116,1

|

33,3

|

190,5

|

8

|

19,0

|

5,600

|

|

5″

|

254,0

|

23,8

|

185,7

|

163,6

|

143,8

|

36,5

|

215,9

|

8

|

22,2

|

6,300

|

|

6″

|

279,4

|

25,4

|

215,9

|

192,1

|

170,7

|

39,7

|

241,3

|

8

|

22,2

|

7,500

|

|

8″

|

342,9

|

28,6

|

269,9

|

246,1

|

221,5

|

44,4

|

298,4

|

8

|

22,2

|

12,600

|

|

10″

|

406,4

|

30,2

|

323,8

|

304,8

|

276,3

|

49,2

|

361,9

|

12

|

25,4

|

18,500

|

|

12″

|

482,6

|

31,7

|

381,0

|

365,1

|

327,1

|

55,6

|

431,8

|

12

|

25,5

|

28,000

|

|

14″

|

533,4

|

34,9

|

412,7

|

400,0

|

359,1

|

57,1

|

476,2

|

12

|

28,6

|

36,000

|

|

16″

|

596,9

|

36,5

|

469,9

|

457,2

|

410,5

|

63,5

|

539,7

|

16

|

28,6

|

46,000

|

|

18″

|

635,0

|

39,7

|

533,4

|

504,8

|

461,8

|

68,3

|

577,8

|

16

|

31,7

|

50,000

|

|

20″

|

698,5

|

42,9

|

584,2

|

558,8

|

513,1

|

73,0

|

635,0

|

20

|

31,7

|

64,000

|

|

22″

|

749,3

|

46,0

|

641,2

|

609,6

|

564,4

|

79,4

|

692,1

|

20

|

34,9

|

72,000

|

|

24″

|

812,8

|

47,6

|

692,1

|

663,6

|

615,9

|

82,5

|

749,3

|

20

|

34,9

|

89,000

|

Cities we supply slip-on flanges to:

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Countries we supply and export of Slip-on Flanges worldwide

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |